-

0

Be established in

-

0+

Professional personnel

-

0 million

Registered capital

-

0㎡

Plant area

There are six production workshops, two installation workshops, one test workshop, more than 160 sets of equipment, and one comprehensive performance test platform for water pumps.

China Mixed Flow Pump Manufacturers and Wholesale Mixed Flow Pump Suppliers

. Main "Double-wheel" brand WFB series non-sealed self-priming pump, GZB, GJB series efficient self-priming pump, SLZW self-priming non-clogging sewage pump, SLG series vertical pipeline pump, SLPWDL series multi-head sewage pump, IH, IS series horizontal centrifugal pump, SCY series liquid pump, ZA, ZE series centrifugal process pump, WQ series submersible pump, etc., for domestic and foreign major steel, electric power, metallurgy, petroleum, chemical, food health, environmental protection and other major industries to provide qualified products and quality services.-

Read More

The self-priming pump is an efficient fluid delivery device with a compact structure design. Its small size and light weight give it significant advantages during installation and movement. The load of the pump is evenly distributed and the mechanical load per unit area is small, thereby reducing the lifting height and reducing the height requirements for the pump room. This feature allows the self-priming pump to be used flexibly in space-limited environments to meet diverse application needs.The structural design of the self-priming pump is relatively simple, easy to operate, and easy to maintain. Users can quickly master its usage without having to possess excessive professional skills in daily operations. In addition, the main components of the pump are usually located above the water surface, making maintenance and repair easier, thus effectively reducing the operating costs and maintenance difficulty of the equipment.Self-priming pumps are widely used in many industries, including chemical, petroleum, pharmaceutical, mining, papermaking, fiber, pulp, textile, food, electric power and municipal sewage projects. Its performance enables it to handle liquids containing solid particles or mixtures, and is suitable for complex working conditions such as ships, showing strong adaptability.During the medium transportation process, self-priming pumps exhibit efficient and stable performance. Its suction range is large, up to 5 to 8 meters, which makes the self-priming pump perform particularly well in applications where media is transported over long distances. In addition, the self-priming pump generates low noise levels during operation, ensuring a quiet and comfortable working environment and providing operators with a good working experience.

-

Read More

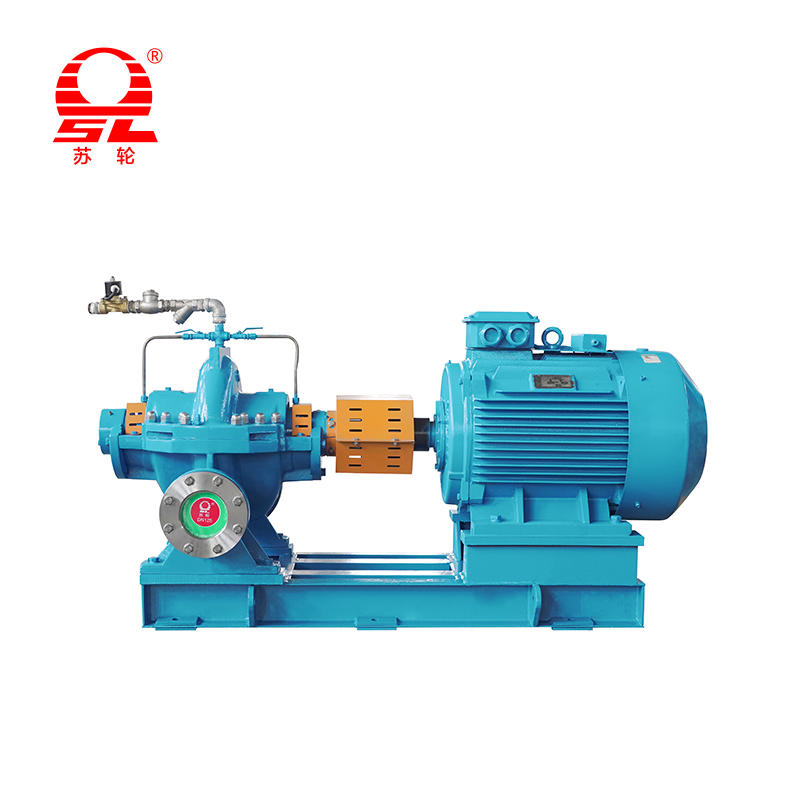

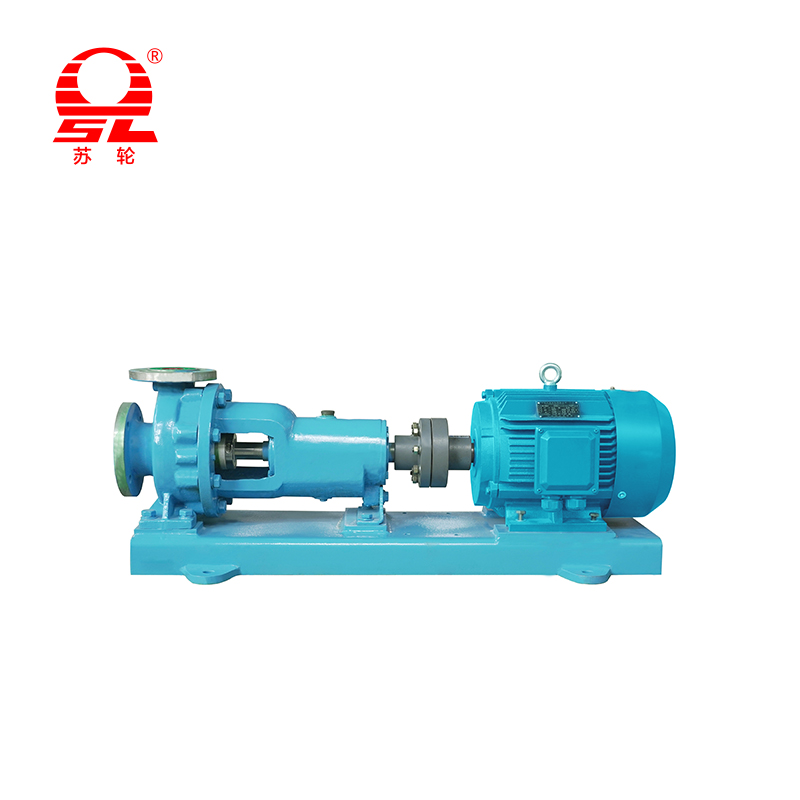

A centrifugal pump is a highly efficient device that transports liquids based on the centrifugal force generated by the rotation of an impeller. Its core working principle is to drive the impeller to rotate at high speed through an electric motor so that the liquid is thrown toward the side channel of the pump body under the action of centrifugal force and finally discharged out of the pump or into the next stage impeller. This process causes the pressure at the impeller inlet to decrease, thereby forming a pressure difference with the pressure of the suction liquid, prompting the liquid to be smoothly sucked into the pump.Centrifugal pumps exhibit efficiency in energy conversion and can effectively convert electrical energy into fluid pressure energy, thereby achieving significant energy-saving effects. Through optimized design, centrifugal pumps can achieve efficient hydraulic profiles, significantly reduce hydraulic losses, and improve overall work efficiency. In addition, the discharge volume of the centrifugal pump can be flexibly controlled by adjusting the discharge valve. This feature not only avoids the risk of unlimited rise of the pressure head but also further enhances the energy-saving performance of the equipment.This pump is widely suitable for transporting a variety of fluid media, including clean water, acid and alkali solutions, and mud. Centrifugal pumps can be manufactured from chemically resistant materials, which makes them capable of pumping corrosive solutions. Therefore, centrifugal pumps are widely used in many industries such as chemical industry, petroleum, paper making, food processing, etc.

-

Read More

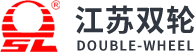

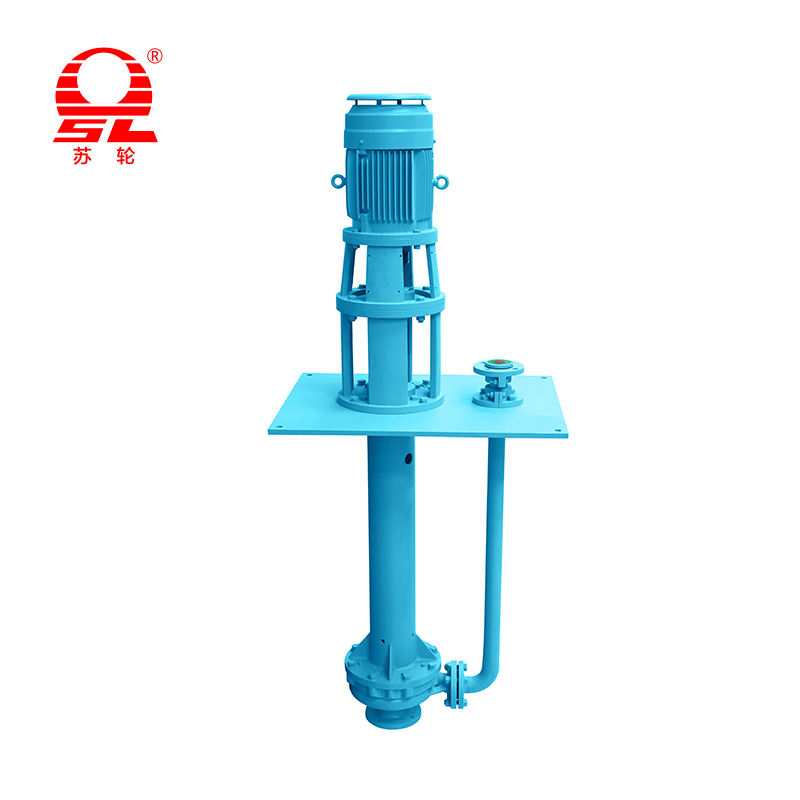

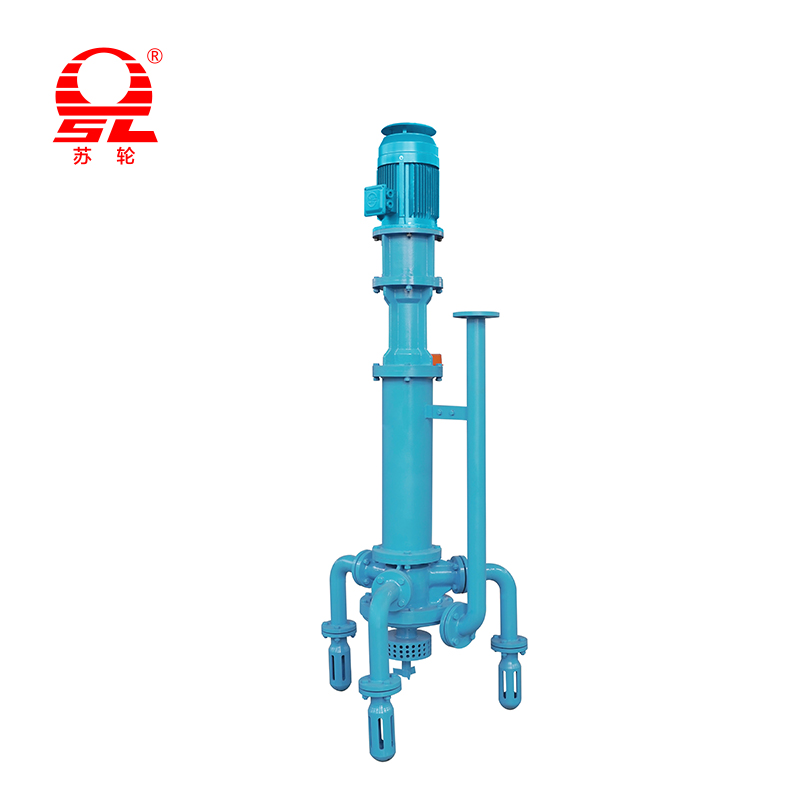

As a type of centrifugal pump, the long-axis pump is derived from the design basis of submersible pumps. Its innovative improvements have made it widely used in industrial and agricultural fields. The long-axis pump has significant flow and lift advantages and can efficiently transport a large amount of liquid to a designated location. It is especially suitable for places with large terrain undulations or where high water levels need to be raised. The stability of its operation stems from the precise design concept and the application of high-quality materials, which not only improves water intake efficiency but also significantly reduces the probability of failure, thereby reducing maintenance costs.Compared with traditional horizontal pumps, the long-axis pump adopts a unique design structure, with the inlet vertically downward and the outlet arranged horizontally. This design not only optimizes the convenience of installation and maintenance but also effectively saves floor space, which is especially suitable for space-constrained environments. In addition, the multi-stage series design of the long-shaft pump uses a long shaft to achieve multi-stage pressurization through the sequential arrangement of multiple impellers and guide vanes, thereby easily meeting the requirements for high-lift fluid transportation. This structure not only improves the lift capacity of the pump, but also enhances its stability and durability.During operation, the long-axis pump evenly introduces liquid into the impeller through the suction bell mouth. The centrifugal force generated by the rotation of the impeller efficiently converts mechanical energy into pressure energy and velocity energy of the liquid. After the rectification process of the guide vane body, the liquid is discharged along the flow path of the external pipe and the discharge elbow. During this process, almost no additional energy is lost, ensuring efficient operation of the pump. In addition, the long-axis pump has performance in water quality adaptability. Whether it is clean water, rainwater, sewage, or media containing tiny particles and slightly corrosive substances, the long-axis pump can easily handle it, fully demonstrating its wide applicability.

-

Read More

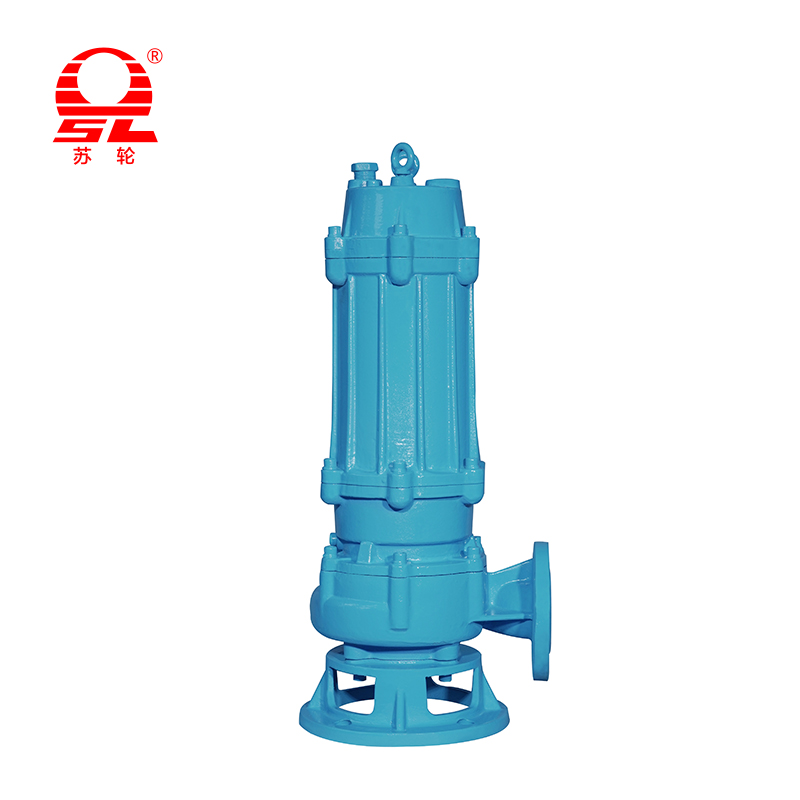

Compared with traditional pump products, sewage pumps can effectively handle sewage containing complex components such as solid particles, fibers, and floating objects, significantly reducing the risk of blockage. The realization of this performance is due to its unique hydraulic component design, especially the anti-clogging design of the large flow channel, which allows the sewage pump to smoothly pass fiber materials five times the pump diameter and solid particles with a diameter of approximately 50% of the pump diameter.The structural design of the sewage pump also reflects its efficiency and practicality. Its compact design takes up little space and can be submersed in liquids, eliminating the need to build a dedicated pump room.The installation and maintenance process of the sewage pump is also very convenient. Small sewage pumps allow flexible and free installation, while large sewage pumps are equipped with automatic coupling devices to simplify installation and maintenance steps. This design enables the sewage pump to be flexibly used in various complex environments, especially in situations where space is limited, and its advantages are even more obvious.

Specializing in "WFB non-sealed self-priming pump", "GJB energy-saving self-priming pump", "IH, IS chemical centrifugal pump", SL multi-suction head PWDL sewage pump, etc..

In 2019, our company invested a lot of money in new intelligent workshops, introduced intelligent equipment, and realized production automation.

In 2020, the company established a special pump testing center, using advanced testing equipment and systems, and more testing methods.

We adopt advanced manufacturing technology, with the robot welding, greatly improve product quality, extend the service life.

Enterprises adhere to the people-oriented, constantly introduce talents, improve management level, has a strong sales team, professional R & D team.

"Double-Wheel" brand series products are exported abroad, covering the domestic steel, electric power, metallurgy, petroleum, chemical, food health, security and other major industries.

-

13

2026/01

13

2026/01

Mechanical Seal Leakage Mechanical seal leakage is the most common failure in vertical pipeline pumps. Leakage may occur during initial pump start-up or after long-term operation. Main causes include seal face wear, agin...

-

06

2026/01

06

2026/01

Significant Energy Savings Vertical pipeline centrifugal pumps are widely used in water supply, HVAC, fire protection, and industrial circulation systems. Traditional fixed-speed pumps cannot adjust flow according to sys...

-

30

2025/12

30

2025/12

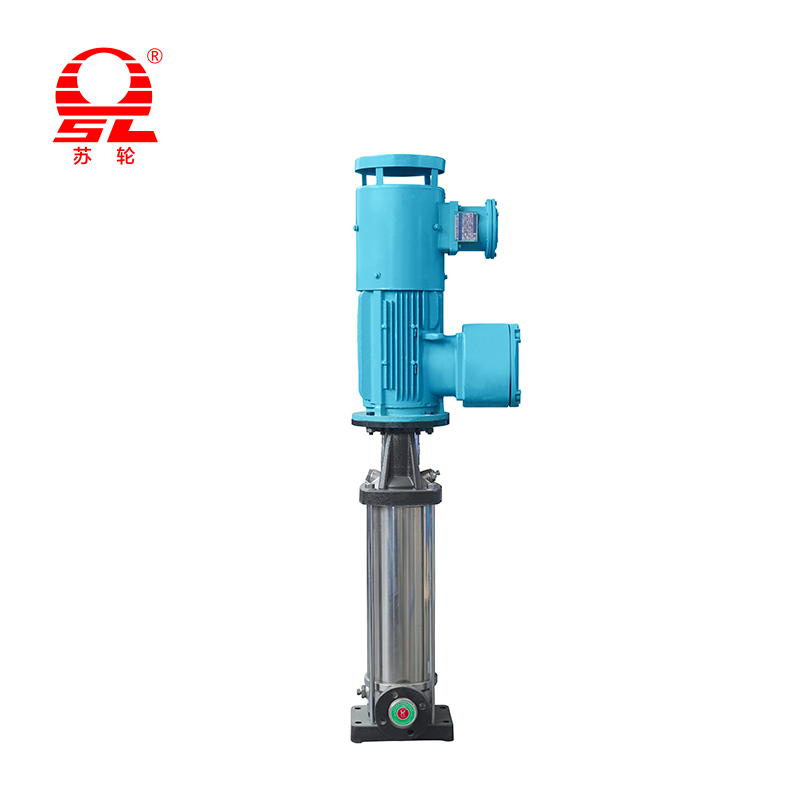

The SLOTS Horizontal Split Case Centrifugal Pump is widely used in municipal water supply, power plants, petrochemical, chemical, and HVAC industries due to its high efficiency, large flow capacity, and reliability. The ...

+86-0523- 84351 090 /+86-180 0142 8659

English

English русский

русский عربى

عربى bahasa Indonesia

bahasa Indonesia